TSf-503 / TSf-303

The Triboster TSf-series is designed for computer-controlled analysis of the static and kinetic coefficients of friction (COF). Each model features crank-shaped biaxial balance technology for precise and reliable measurements.

Different loads, speeds, contact parts, measuring methods, and options allow customers to set up the instruments to meet their needs.

These versatile models feature linear reciprocating movement. The stage’s stroke can be set from 1 to 80mm and the speed from 0.1 to 100mm/sec.

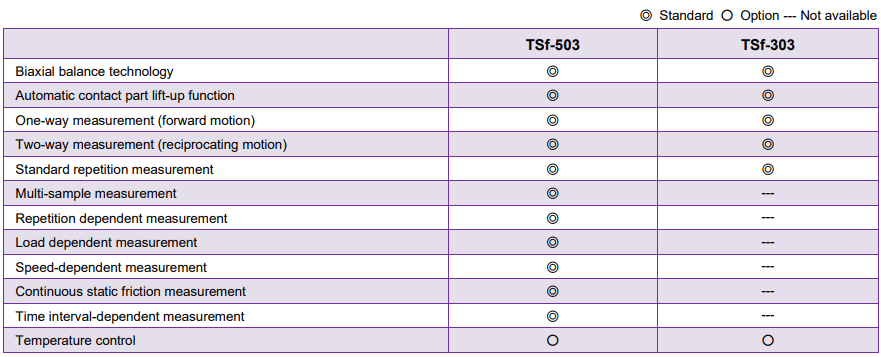

The TSf-503 features seven measuring methods, a complete set of six weights, and a built-in temperature sensor.

The TSf-303 features one measuring method (standard repetition measurement) and two different weights. A temperature sensor is available as an option.

Features:

- Biaxial balance technology: This technology minimizes the effects of inertia and other external forces on the load cell during the measurements, ensuring exact and reliable results.

- Two-way measurements: Measurements of coefficients of friction in both ways of the stage travel.

- Automatic counterpart lift-up function: The counterpart lifts automatically after every measurement of the coefficient of friction in one way of the stage travel to avoid contact with the sample when the stage returns.

- Continuous static friction measurement: The stage’s stop-and-go movement allows for measurements of up to 50 data of coefficients of static friction in one stroke.

- Standard repetition measurement: The device repeatedly measures friction coefficients on the same measuring area in up to 12 cycles.

- Repetition-dependent measurements: The device repeatedly measures friction coefficients on the same measuring area in 100 to 10.000 cycles.

- Multi-sample measurements: Measurements of friction coefficients for different samples or areas for one test piece allow easy comparison.

- Load-dependent measurements: Measurements of coefficients of friction depending on different normal loads.

- Speed-dependent measurements: Measurements of coefficients of friction depending on different speeds.

- Time-interval dependent measurements: The software analyzes the influence of adhesion to the coefficients of friction depending on up to four different contact times in one way, combining the counterpart lift-up function and the stage’s stop-and-go movement.