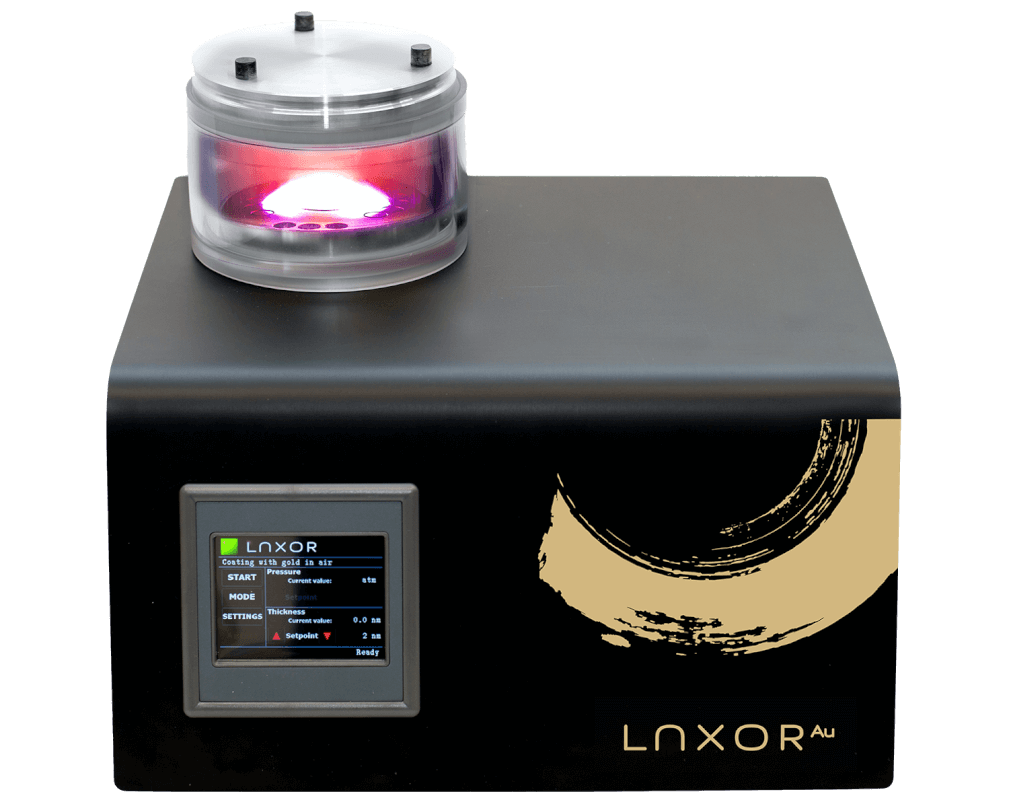

The LUXORAu is an advanced, fully automated sputtering device that applies a fine grain gold coating from 1 to 100 nm thickness. This allows you to get the very best SEM imaging quality from your samples.

LUXOR’s unique A² technology creates a controlled plasma in the process gas. In the plasma, ions are accelerated by means of high voltage and directed onto the gold target. Finest gold atom clusters are thereby released from the target and coat your samples in a precise manner, resulting in an extremely uniform, thin and homogeneous gold layer.

The LUXORAu is also renowned for its ease of use and quick, hassle-free operation.

OPTIMISED USER INTERFACE

First of all, the LUXORAu is remarkably easy to use. Using the built-in touchscreen, the coating process can be initiated with just a few clicks.

SUPERIOR GOLD COATING RESOLUTION

Field tests clearly show that the LUXORAu generates more homogeneous and smaller gold grains, compared to other coating instruments in the market. Furthermore, the A² technology ensures identical, reproducible coating results, day after day and year after year.

INCREASED SPEED & EFFICIENCY

ADVANCED SEM PROTECTION

The unique ‘upside down’ design of the LUXORAu makes sure that loose particles will be removed during the coating process. This way, your SEM is optimally protected.

ROBUST DESIGN, MADE IN GERMANY

Despite its modest footprint and elegant appearance, the LUXORAu is a robust, sturdy device. It is designed to be used intensively and run hassle-free for many years.

Specifications:

- Au coating with air or argon

- Maximum capacity: 7 x Ø 12.5 mm or 3 x Ø 25 mm stubs

- Average coating time: 5 minutes (based on a 10 nm gold coating)

- Additional vacuum & drying modes

- Low energy dual stage pump

- Vacuum & drying modes: 7 Pa to 150 Pa (continuously selectable)

- Process time: 1 to 600 minutes (continuously selectable)

- Gold layer thickness: 1 to 100 nm (continuously selectable)

- Process chamber: Borosilicate glass Ø 100 mm x 150 mm height

- Implosion shield: PET Ø 120 mm x 150 mm height

- Vacuum connector: DN 16 KF

- Gas supply: Air or argon (0,6 bar)

- Dimensions: 340 x 340 x 290 (mm, W x D x H)

- Weight: 11 kg

VACUUM PUMP

- Can be ordered separately as “pump kit” including

- Two-stage roughing-pump with a pump capacity of 4.8 m³/h

- Metal vacuum hose, DN 16 KF, length 1 m

- 2 x fittings and 2 x seals DN 16 KF

- 1 x oil mist filter