Clearance monitors automate the task of clearing large objects and waste for the presence of contamination.

RTM661/440™

Quick and accurate scanning of items such as larger tools, boxes, or even a small waste drum.

The RTM661/440 monitor is designed for the reliable release measurement of various objects such as tools, waste bags or brief cases.

Its fast, integral gamma measurement is based on the use of gamma plastic scintillation detectors in line with modern PC-based counting electronics. The system is based on an industrial personal computer.

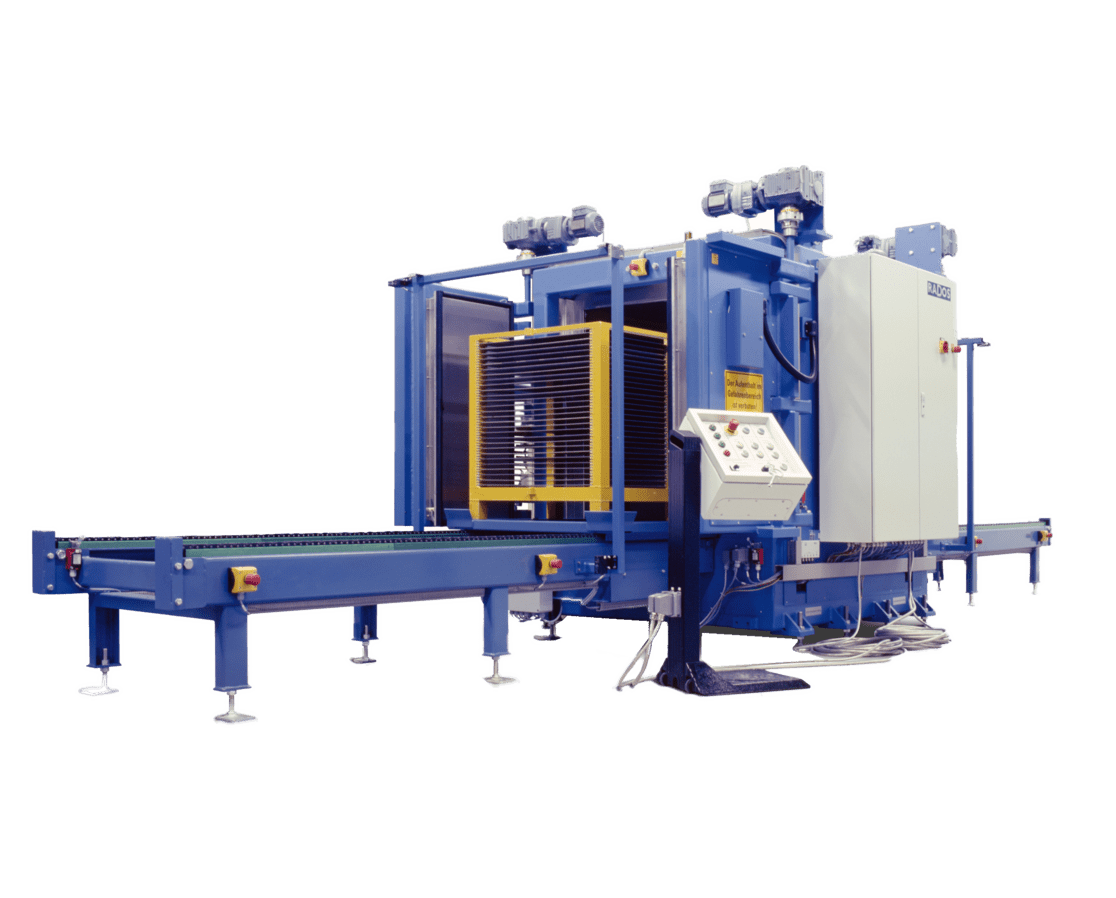

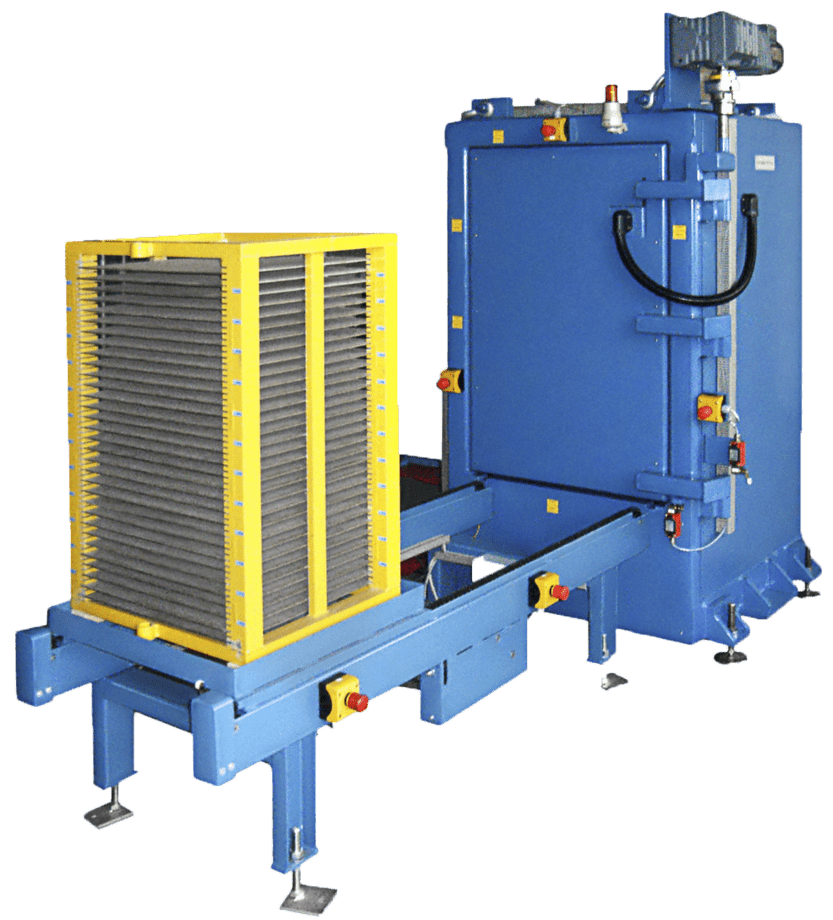

RTM644INC™

A conveyor-based clearance monitor for quick and accurate scanning of large items, grid boxes, etc.

The RTM644Inc system is an industry leading clearance monitor for large objects such as palettes, waste bags, grid boxes, 200 l and/or 400 l drums checking for gamma radiation. The goods to be measured are moved into the chamber by a conveyor system.

24 large-area gamma-plastic-scintillation detectors are arranged in 4π geometry ensuring high sensitivity and low detection limits. Geometry and weight of goods are considered, compensating self-shielding effects.

Measurement parameters can be matched to specific requirements.

RTM661/540™

The RTM661/540 system is the largest monitor of the RTM661 family using the same software and filling the final level in reference to customer chamber size requirements.

Through the use of a conveyor system loading and unloading of the chamber is done with ease. Automatically controlled door and weight scale rounds out this monitor. With its ability to support 200 Liter drums in its chamber, it is ideal for mass volume through put.

RTM640INC™

The RTM640Inc system is a unique waste monitor designed to clear large amounts of material or drums.

Through its specialized programs, it can determine the right path of disposal for the material being measured. In addition, the system can help to pinpoint the area of highest activity thus providing the operator the ability to remove it and re-measure until it meets the clearance criteria.

GAS BOTTLE MONITOR™

The Gas Bottle Monitor is a clearance measurement monitor for contamination on the surface of pressurized gas bottles.

The Gas Bottle Monitor is a final barrier against the transfer of unacceptable levels of radioactive contamination on the surface of pressurized gas bottles, from radiologically controlled areas to clean areas.

One single operator can manually load the gas bottles that can differ in height, into the measurement chamber. The operator can easily monitor and control the process via the touchscreen, and the interface provides visual and acoustic guidance.