The Ultrasonic spray system for Solar Cell & Fuel Cell, Photoresist, MEMS, & Other Nanotechnology Applications

GENERAL INFORMATION:

Sono-Tek Corporation is a world leader in ultrasonic atomizing nozzle systems for applying precise, thin film coatings. Major industries utilizing our ultrasonic nozzle systems include fuel cell PEMs, thin film solar cells, carbon nanotube suspensions, anti reflection coatings, CIGs, float glass coatings, medical nanocoatings such as implantable device coatings onto stents, catheters, balloons and pacemakers, and any other spray application requiring uniform deposition with minimal overspray.

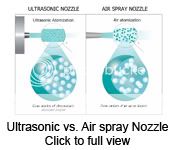

Sono-Tek spray system has been widely used in scientific research and industrial production. The ability for Sonotek nozzles to break up nano-particle clusters in suspension due to ultrasonic shearing forces makes them ideal for achieving a very uniform and high quality layer when compared to other  methods. methods.

In addition to this Sonotek ultrasonic nozzles also:

- Reduce waste

- Are non-clogging and corrosion-resistant

- Have a narrow drop size distribution

- Produce a highly controlled soft spray

Expensive materials delivered through conventional nozzles can produce material waste through overspray , but can be more efficiently transferred with a more controlled method using Sono-tek spray systems.

FUEL CELL COATING APPLICATIONS

Fuel cell carbon catalyst ink films created with ultrasonic nozzles exhibit several key advantages when compared to conventional coating techniques: Platinum films deposited with Sono-Tek ultrasonic spray methods have coating efficiency optimized above 90% efficient with repeatability at ±1 percent.

SOLAR CELL COATING APPLICATIONS SOLAR CELL COATING APPLICATIONS

Ultrasonic nozzles offer similar benefits to those described for fuel cell production in the deposition of active layer coatings such as CIG(s), CDTe, and CZTS onto thin film solar cells. Transfer efficiencies as high as 95%, reduce consumption of expensive raw materials, ideal for maximizing efficiencies in the deposition of very thin micron layers of nanomaterials.

Read more on Solar & Fuel Cell applications… Read more on Solar & Fuel Cell applications…

|