MEMCAST™

The MemCast™ automatic casting machine is ideal for the automated synthesis of flat sheet polymeric membranes. This state-of-the-art machine allows for the precise creation of membranes with varying thicknesses by applying a thin film of polymer solution.

After the immersion in a coagulation bath, this results in the formation of the final membrane via wet phase inversion. Whether you need self-standing film layers, or you prefer to cast on various substrates, MemCast™ offers the ultimate solution.

Specifications:

| Casting size | ca. 350 x 560 mm |

| Casting speed | 0.1 up to 10 cm/s |

| Heating of the coating surface | up to 60 °C |

| Standard casting knife | 1 compartment and 4 thicknesses (M1G4) for casting films with a wet thickness of 100 µm, 150 µm, 250 µm and 500 µm |

Key Features:

- Reproducibility & accuracy

- The MemCast™ guarantees homogeneous and reproducible membranes, minimizing variations and inconsistencies that are often encountered in manual processes.

- Adjustable speed & temperature control

- With easily adjustable settings for coating speed and temperature, the MemCast™ ensures optimal casting conditions tailored to different formulations, enhancing membrane quality and consistency.

- Safety & ease of use

- The one-arm casting design enhances operator safety and allows for easy removal of the casting plate. Additionally, the MemCast™ features a user-friendly mechanism for securely attaching and detaching the coating support, making the transition to the coagulation bath quick and effortless.

- Versatile & durable design

- Compatible with different coating supports, with a tempered glass plate for long-lasting performance. Custom-made knives are available upon request, allowing for tailored casting options to meet specific needs.

Accessories:

- Custom made casting knife in aluminium

- The width of the knife is either 380 mm (for casting of 355 mm wide membranes) or 190 mm (for casting 165 mm wide membranes).

A wide range of customized casting knives is available offering different casting thicknesses. The user can select up to 4 thicknesses. The thickness can vary between 50 µm and 1000 µm.

- The width of the knife is either 380 mm (for casting of 355 mm wide membranes) or 190 mm (for casting 165 mm wide membranes).

- Coagulation bath

- Special bath to submerge the produced membrane in a nonsolvent bath, which allows for final formation of the membrane by means of solidification.

- Glass casting plate with special clamp

- A glass casting plate with special clamp to attach nonwoven fabric or another substrate layer.

- Casting plate in stainless steel 316

- Custom made casting knife in stainless steel 316

RotaMem

The RotaMem is designed for the automatic centrifugal potting of hollow fiber membranes into R&D modules using 2 composite potting glue. The process starts by placing two modules, containing the hollow fibers, together with the casting container together with the dosing system, into a holder. This module holder is then positioned on a rotor in the drawer that slides out from the centrifuge. The process can start when the drawer with modules and casting container is slid into the potting chamber.

Upon starting the selected fabrication program, the module begins to rotate and the potting chamber is heated to the required process temperature. As the centrifuge reaches the specified parameters, polyurethane or epoxy resin is introduced into the casting container through a central opening in the centrifuge lid. The centrifugal forces generated cause the resin to flow from the casting container into the head area of the modules. Once the resin hardens, the centrifugal plate stops rotating, allowing the modules to be removed from the potting chamber.

Specifications:

| Compatibility | Designed for modules made from Tritan copolyester up to 150 mm in length and max. diameter 20 mm, with potting made of epoxy or polyurethane 2k resins |

| Chamber Dimensions | 170 mm x 176 mm x 93 mm |

| Capacity | Maximum weight of centrifugal plate with modules and glue distribution up to 500 g |

| Adjustable Rotational Speed | 300-1500 ± 5 rpm |

| Temperature Control Range |

Room Temperature to 50 °C ± 5 °C |

| Control Panel |

Set and monitor temperature, rotation speed and process duration with ease |

Key Features:

- Consistent potting quality

- The uniform glue distribution ensures a sharp, reproducible border between the potting block and the active part of the hollow fiber bundle, preventing capillary rising of glue along the fibers. This guarantees that all fibers are evenly glued, while also ensuring better thickness control.

- Precise temperature control and adjustable rotation speed

- The RotaMem maintains precise temperature control to ensure reliable and consistent results. The rotation speed is also adjustable, allowing you to tailor it for optimal potting conditions.

- Programmable procedures and flexible data storage

- Create and store multiple procedures for time, temperature, and rotation speed. Additionally, process data can be exported to a USB stick for analysis and quality control.

- Enhanced safety features

- The RotaMem is equipped with process control features to ensure safe operation. The inspection lid with glue dispensing window allows easy access for inspection and precise glue application. Visible alarms provide clear notifications when set points are reached.

MemCut

The MemCut is designed to standardize your trimming procedure of hollow fiber membrane modules after potting into a polymeric housing. The instrument is capable of manual cutting of PUR/Epoxy block of max 60 mm in diameter with recommended hardness between 40-60 Shore D.

Engineered for excellence, the MemCut ensures clean, reproducible cuts every time.

Specifications:

| Compatibility | Cutting of membrane modules of max 60 mm in diameter and 500 mm length |

| Capacity | 1 cutting 19-degree edge with 16-degree relief |

| Blade material | Hardened steel, specially designed for cutting hollow fiber membrane modules |

Key Features:

- Robust standalone design for easy operation

- Built with a durable metal body, the MemCut ensures stability and longevity, making it a reliable tool for any laboratory.

- Sharp and precise cuts that maintain fiber integrity

- The MemCut is equipped with a top-tier blade made of quality hardened steel. This ensures sharp, precise cuts that preserve the integrity of the fibers.

- Comprehensive hand protection for safe operation

- Your safety is our priority. The MemCut is designed with comprehensive hand protection, ensuring safe operation without compromising performance.

- Minimal particle generation for a clean and qualitative end product

- The precision design of the blade and MemCut body minimizes particle generation during the cutting process, enhancing the quality and cleanliness of the final product.

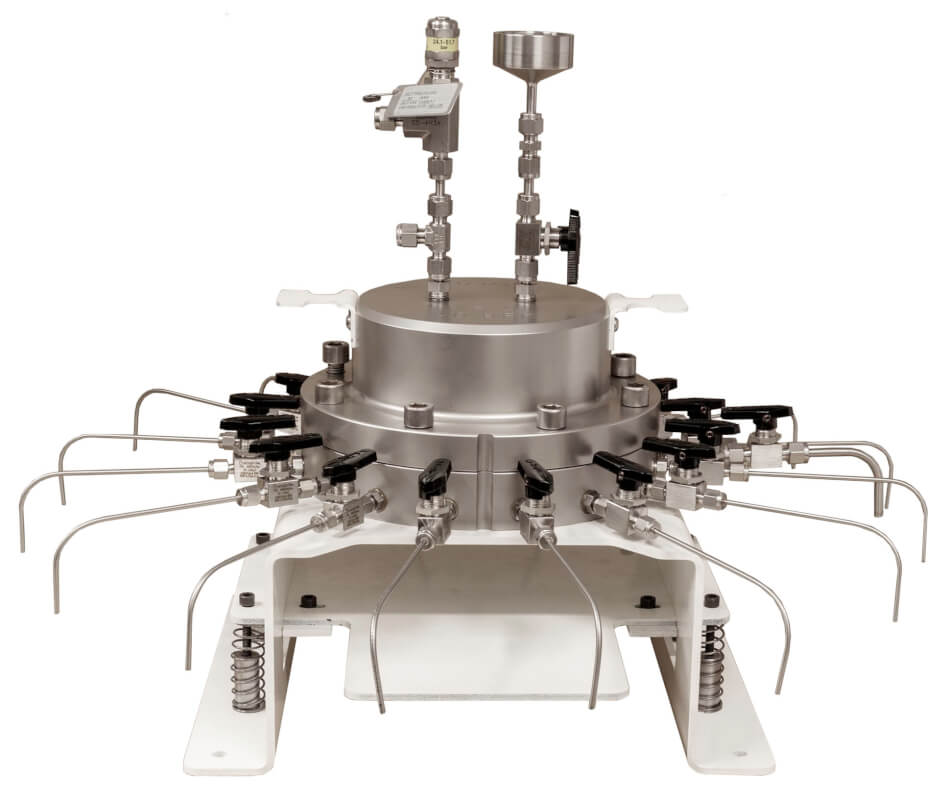

Spider

The Spider is a high-throughput dead-end filtration module designed to revolutionize liquid filtration workflows. Capable of performing up to 8 or 16 simultaneous filtrations (depending on the model), the Spider drastically reduces experiment time while ensuring reliable and precise results.

Built from robust stainless steel, the instrument is compatible with both aqueous and non-aqueous feed solutions, making it a versatile and essential tool for modern membrane laboratories.

The Spider workflow is simple: membranes are placed inside the sample holder, the chamber is sealed, and the feed reservoir is filled with the selected solution. By applying the desired pressure, individual permeates are collected in separate bottles for analysis, while the remaining retentate can also be retrieved.

Specifications:

| Compatibility | Suitable for both aqueous and non-aqueous feed solutions |

| Capacity | Common feed reservoir for testing of multiple membranes in the same run. Can carry up to 8 or 16 simultaneous dead-end filtrations |

| Magnetic stirring | Ensures a homogeneity of the feed solution and reduces concentration polarization as well as membrane fouling |

| Max. pressure | Full safety models available up to 40 bar pressure |

| Support grids and O-rings | All Spider models are supplied with porous metallic supports grids for each membrane cell and EPDM rubber O-rings to ensure tight sealing |

| Sample area & max. feed volume |

201,06 mm² and 350 ml, depending on the Spider model |

Key Features:

- High throughput

- Conduct up to 8 or 16 filtrations simultaneously, saving significant time compared to single-cell experiments.

- Versatile applications

- Suitable for both aqueous and non-aqueous feed solutions across various research fields.

- Robust, reliable and safe

- Durable stainless-steel construction ensures long-lasting performance.

- Streamlined workflow

- Collect multiple individual permeates and retentate for detailed analysis at the same time.

- Precision under pressure

- Consistent pressure control guarantees repeatable and accurate results.